Aviation

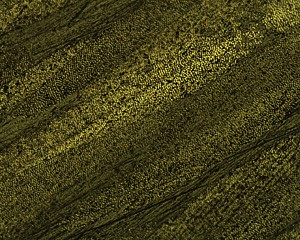

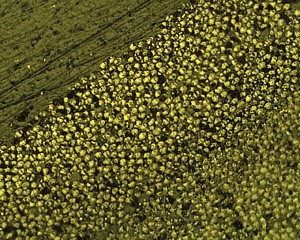

Modern aviation, both military and civilian, is a prime example for use of advanced composites. Demands made by the aviation industry for materials that are both light and strong have been the main force driving the development of composites. It is common now to find wing and tail sections, propellers, rotor blades and even turbine blades made from advanced composites, along with much of the internal structure and fittings. The airframes of some smaller aircraft are made entirely from composites, as are the wing, tail and body panels of large commercial aircraft.

In thinking about planes, helicopters, UAVs, and other aerostructures it is worth remembering that composites are less likely than metals (such as aluminum) to break up completely under stress. The fibers in a composite can act to block the propagation of small cracks and to distribute stress.